Posted by J on May 17th 2021

Cutting OD thread on CO2 laser with rotary

Not everyone has a lathe in their garage. However, if you have a rotary, you may make a coarse thread using a CO2 laser. Wood has burn which is not easy to work with, so we are using acrylic this time.

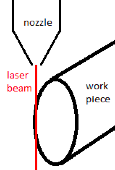

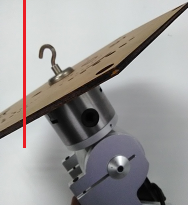

First we cut a 22mm diameter cylinder from a thick piece of PMMA. You may glue it to a long cylinder for easy clamping. Then we clamp it carefully to minimize runout. We use a 4" focal length lens to make the beam dot small even when the beam is far away from the nozzle; the nozzle cannot get too close to the workpiece, so a short focal length like 2" does not work well. You may remove the nozzle to get more space but you need to make the air assist blow from another source. We draw a straight line in the program using the pitch and circumference we measured. After cutting a few passes, it fits into the female thread. We moved the x,y starting position between passes, but the u axis staring angle is always zero. The thread shape done by a lathe is better, but we are just cutting a thread for the lens retaining ring. This coarse thread does its job.

https://lightobject.com/high-precision-rotary-for-cnc-or-co2-laser-machine/

Something more on rotary:

When mounting the rotary at an angle, we can cut angled gear teeth. Draw a zigzag line. It does not make an ideal gear profile, but it is faster than regular wood working.