Feb 10th 2022

Aligning laser machine bed Z table

Sometimes crashes happen, we need to realign the work table. BTW, We carry DIY kit to build a motorized z table. To make discussion simple, we assume the laser beam go straight down the center of the laser head. To make sure the distance between laser head nozzle and the table to be constant, we should make the z movement perpendicular to the xy plane.

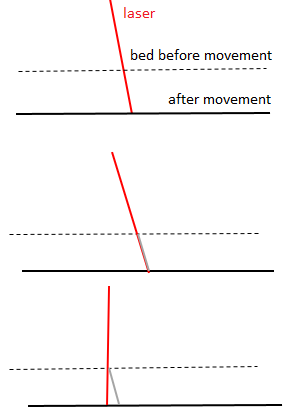

Here are three cases. The first one is that table movement is perpendicular to the table. Second case is that the laser is parallel with the table movement. If you move the z table up/down, the two burn marks on the material will be at the same spot. Cutting edge will not be straight though. We can adjust the corners to make the table perpendicular to the table movement. Or put something thin under the lower side of the table for quick small adjustment.

The last case shows the table movement is not perpendicular to the laser beam. After making the laser beam parallel to the z table movement, it becomes the second case above. However, the third case still works well for many laser jobs.

This may be too much work if you are not a perfectionist. When using laser machine, we don't cut a second time after moving the z table very often. With an 8degrees error for example, moving the z table 1" will only shift the cut by 0.01". We can simply adjust the second cut by 0.01" in the software.