Aug 24th 2021

A Closer Look at Glass Laser Tube

Some of you may have never looked at the light inside the laser tube. Glass and laser does not absorb much visible light, so we are able to see the pink light. At low mA, you can see the pink light at the end of the laser tube; the light at mid section of the tube is faint. As mA goes higher, the pink light section becomes longer. If you see thick/faint purple light at high mA, the laser tube may be bad. By the way, sometimes you see the pink light moves around the metal ring; it is normal.

The following pictures are from a 130W tube's output end: At low mA not stable, the center of the beam looks bright. When the beam becomes stable, the beam becomes thicker, and the color of the beam is more uniform.

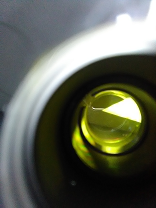

The following picture is the view through the tube's output window. The window reflect about half the Laser and let the other half pass through. This side can get hot after use, so you see the water cooling channel or heat sink on this side of some Laser tubes. Please keep this output window CLEAN. Dirty window can damage the Laser tube. But do not clean too often because it gets scratched a little bit every time you clean.

You may wonder how much power loss is there every year. Large tubes does not drop much power <3%. It is more obvious on small tubes <50w. As an extreme case, we left a 150w JK laser tube exposed to sunlight for 2 years. The power loss was only 20%.

Service story:

When you need to transport a laser machine for repair, it

is good to take out the laser tube. Even if the laser tube is not firing, we only need to test the laser power supply. If the laser power supply is good, the laser tube is very likely bad. A JK laser tube survived in a machine after traveling 300miles; maybe the truck's

suspension was good. You may not have luck with other brands' fragile

laser tubes.

When water is not changed and becomes dirty, it is hard to clean the inner tube even with steel wire. Using acid to dissolve dirty thing is not fun. It is wise to keep the water clean.